Without distribution lines as the terminal conduits, high-voltage electricity cannot reach end-users—much like blood failing to reach cells when capillaries are severed. Terminal demand is left waiting in vain. Therefore, fault inspections for distribution lines are far from mere routine checks that can be perfunctorily handled.

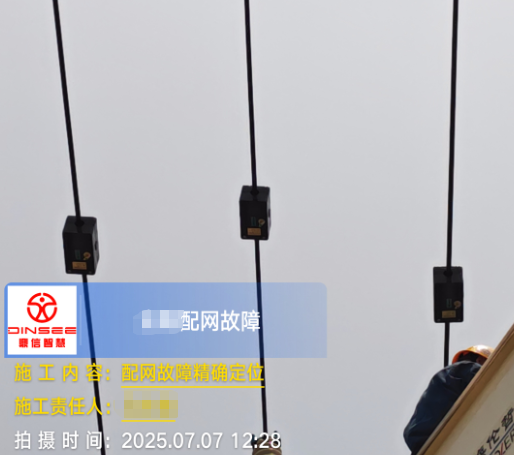

In response to this situation, Dingxin Smart Technology has independently developed and launched the DX-WPS100-GZ03 Distribution Network Overhead Line Insulation Defect Dual-End Locator, also known as the Distribution Network Traveling Wave Fault Locator. The device consists of a locator unit + Dingxin Smart Diagnostic System + client application. Specifically, the dedicated conductor locator collects fault current and voltage signals from the line, uploading real-time fault information to the diagnostic system. Utilizing artificial intelligence deep learning algorithms, it diagnoses and outputs fault diagnosis results. These results are pushed to maintenance personnel via alert text messages, and relevant information can be viewed in real-time through the web client.

Distribution line faults often lie hidden in the "small details,"while Dingxin Smart Technology'sOverhead Distribution Line Insulation Defect Dual-End Locatorcan pinpoint faults within <100 meters, achieving over 95% reliability and identification rate for fault location.

Hidden Hazard Early Warning Level

The real-time sensing capability of this device overcomes the limitations of traditional post-incident detection during routine inspections. Specialized positioning devices installed on conductors feature high-frequency sampling capabilities, enabling them to capture faint traveling wave fault signals during distribution line operation. These signals are wirelessly transmitted in real time to the diagnostic system. The system's artificial intelligence deep learning algorithms compare and analyze historical data against a fault signature database, triggering early warning mechanisms. Alerts are delivered via SMS and web notifications to maintenance personnel's mobile devices and platforms, enabling the identification of potential hazards at their earliest stages.

Fault Location Process

When faults such as short circuits or grounding occur on power distribution lines, high-frequency traveling waves propagate from the fault point toward both ends of the line. The location device captures these traveling wave signals within microseconds and records their arrival times. Specifically, the adoption of a dual-timing system utilizing BeiDou and GPS provides a unified time reference for all monitoring terminals along the power distribution line. This achieves clock synchronization accuracy of less than 100 nanoseconds across all monitoring points within a wide area. In other words, even when monitoring terminals are distributed along power distribution lines spanning tens or even hundreds of kilometers, the time difference error in capturing fault traveling wave signals between different terminals can be controlled within an extremely small range. This range is far smaller than the theoretical propagation time difference caused by variations in line distance.

By applying the dual-end locator for insulating defects in overhead distribution lines, the challenge of "inaccurate and slow fault location" in distribution networks has been transformed into "accurate and rapid fault detection." This enables power maintenance personnel to significantly reduce fault troubleshooting and repair times, ensuring end-users no longer endure unnecessary delays in meeting their electricity needs.